Case

the effect of roll diameter on mill capacity

2023-03-23T14:03:44+00:00

The effect of roll diameter on mill capacity

The effect of roll diameter on the capacity of a mill is not well established It is complicated by a likely interaction with mill speed A rudimentary, theoretical approach is used to advance the thesis that mill capacity is fundamentally proportional to the diameter of the mill rollsThis study investigated the effect of the stud diameter on the capacity of a studtype HPGR using the discrete element method with a breakage model To evaluate the effect of a stud diameter, which is placed on a roll surface, simulations were performed for three types of HPGR having 13, 6, Effect of the roll stud diameter on the capacity of a high The roll size of a roll crusher was 305 cm × 901 cm Gypsum rock (SG = 27, bulk density = 17 t/m 3) is to be crushed Determine 1 the set in order to crush at the rate of 12 t/h and 10 rpm speed of the rolls, 2 the ratio between capacity and peripheral speed if the set was 25 cm, 3 the nip angle when the crusher feed size is 10 cm,Roll Diameter an overview ScienceDirect Topics1 Increase Roll Neck Diameter (from 595 to 610 mm) Mill design attributes Roll barrel diameter: 990 mm Barrel width: 2240 mm Roll neck diameter: 610 mm Roll neck to barrel ratio: 62 percent New Timken bearing Bearing: fourrow tapered roller bearing NPNP (shown in Figure 13) Envelope: 610000x844550x615950 [ID x OD x Width in mm]Technical Article Rolling Mills RevampNov 27, 2015 This affects the roll life and increases the roll cost per ton It is a fact that all mill rolls eventually deteriorate and the roll passes need to be changed to achieve size control and finished product surface quality When the roll diameter reduces to less than the minimum diameter required by the mill stand after turning down, then the roll Understanding Rolling Process in Long Product Rolling Mill

1 Hot rolling and rolling defects: 11 Front and back

We have seen that the rolling load is dependent on roll diameter, higher the roll dia, higher the roll force Similarly, smaller reductions requires lower roll force In order to reduce the roll force, we can reduce roll diameter, or reducing the friction Another method of reducing rolling force is to apply a small tensile force on the stripselective cooling nozzles is in conjunction with the shape measuring roll on the mill exit side The relevant nozzles in the top and bottom header of the same zone are operated simultaneously, so that both top and bottom roll share the same reaction Selective cooling has an immediate effect on the roll diameter in this particular zone,GENERAL ASPECTS OF ROLL COOLING FOR HOT COLD o Machine part blank diameter to specifications outlined in chart o Included angle of blank is 1 °47’ o Verify blank diameter at location Y [column “Y” and “BD@Y”] o Roll the thread until the pitch diameter gages within the L1 L2 gage specifications o Adjust the blank diameter, until the Major diameter gages within 6 –Step gageThe Basics of Thread RollingSep 13, 2013 A 750 mm diameter calender roll for example, ground perfectly, will go out of shape done at the mill or at an outside roll shop Published September 13, 2013 Practical Roll Techniques: • Dampening effect of the machine Roll balance is influenced by face length, core construction, and the deflection of a roll rotated at speed Practical Roll Techniques Grinding BalancingWork Roll Diameter Work roll diameter and center distance in a roller leveler determine the machine's thickness capacity (see Figure 3) Minimum thickness is determined by how small of a radius the material can be bent into with a given roll size Maximum thickness is determined by the maximum load a given roll can safely and reliably handleLeveling flatrolled strip The Fabricator

TwoRoll Mill Rubber Tyre Machinery World

Apr 27, 2015 The front roll is smaller in diameter as compared to the back roll And hence when you see a refiner mill identified as 21″ x 24″ x 36″, you simply need to decode it as Front Roll diameter is 21 inches, Rear Roll diameter is 24 inches and both the rolls have same face length of 36 inchesCalculates the outside diameter of a roll of material when the rolled length of the material, thickness of the material, and diameter of the hole in the center or the tube on which the material is wound are given An example of rolled material would be a rolled carpet or a rolled sheet of paper from the paper mill The length units that can Calculator for Outside Diameter of Roll of MaterialJul 01, 2008 A continued requirement for everfiner product (nanometer range) and advances in mill technology have led to the development of even finer bead size ranges (01 05 mm) (Figure 1) Milling Actions Grinding, or deagglomeration, is affected by impact, pressure and shear forces between the grinding media and the mill partsMilling Media Review Part 2: Bead Density EffectJun 18, 2014 Roll Pass Design satyendra; June 18, 2014; 1 Comment ; Long products, roll grooves, Roll pass, Roll pass design, rolling mill, rolls, sections,; Roll Pass Design Long products are normally rolled in several passes, whose numbers are determined by the ratio of the initial input steel material (square or round billet or bloom) and final cross section of finished productRoll Pass Design – IspatGuruHowever, particle size distribution is again a problem, and roll presses are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill This gives good cement performance, and reduces energy consumption by 2040% compared with a standard ball mill system Capacity of cement millsCement mill Wikipedia

Hammermills versus roller mills Worldgrain

The use of differential roll drive arrangements, which create a sheer effect between the chills, not only allows for a finer particle size output, but the sheering effect the roller mill has upon starch granules in cereals is advantageous to the nutritionist when compiling rationsThe mill must be large enough to do the job, the shafts heavy enough to withstand bending, and the castings large enough to house the shafts and bearings, but the mill must be small enough to minimize the distance between the points where the roll contacts the material The diameter of the shafts and their effect on the throat diameter of the Exploring the welded tube making process: The basics for To determine the size of mill drive required, factors such as the diameter and weight of the jar mill should be considered the largest diameter jar that could be used on this series of roll drives is a 10″ diameter jar, the length of the jar and the number of grinding jars to be used simultaneously If it were desired to grind four 5″ diameter by 8″ long jars at one time, 4 x 8″ + 2 Mill Jar Bottle Roller Drives 911Metallurgisto Machine part blank diameter to specifications outlined in chart o Included angle of blank is 1 °47’ o Verify blank diameter at location Y [column “Y” and “BD@Y”] o Roll the thread until the pitch diameter gages within the L1 L2 gage specifications o Adjust the blank diameter, until the Major diameter gages within 6 –Step gageThe Basics of Thread RollingOct 07, 2013 Typically, optimal crowning is 75 percent of nominal capacity, with all things—yield, width, diameter, pinch pressure, and speed—being equal For instance, a machine with 1in nominal rolling capacity will form very nice 075inthick cylinders (under the right pressure), with all surfaces parallel to each other and producing the same Don’t get flattened by the wrong plate roll

Rolling Mills: 6 Different Types of Rolling Mills [Images

Sep 30, 2020 In the rolling process, the job is drawn through a set of rolls due to interface friction, and the compressive forces reduce the thickness of the workpiece or change in its crosssectional area The types of rolls used in rolling mills are depended upon the shape, size and the gap between the rolls and their contour Because of workability and limitations in equipment, rolling is done in the Jul 08, 2016 An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classification performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit Mass balance of the circuit was done by JKSimMet Effect of ball load and size distribution on grinding and Slice Mill™ Slice Mills™ are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only difference is that they are as little as 12” in length Since mill diameter dictates performance and mill length only affects capacity, Slice Mills™ are used to Mill Speed New Drying, Mixing, Blending, and Size • Roll diameter: normally from 100 and 120 mm as a function of the roll paper length and embossing type; actually “big” jumbo kitchen rolls up to 160 mm diameter are distributed in the consumer market • Number of services/sheets • Service length: normally from 210 and 240 mm • Core diameter: normally from 38 to 50 mmIntroduction to process and properties of tissue paperCalculates the outside diameter of a roll of material when the rolled length of the material, thickness of the material, and diameter of the hole in the center or the tube on which the material is wound are given An example of rolled material would be a rolled carpet or a rolled sheet of paper from the paper mill The length units that can Calculator for Outside Diameter of Roll of Material

Milling Media Review Part 2: Bead Density Effect

Jul 01, 2008 A continued requirement for everfiner product (nanometer range) and advances in mill technology have led to the development of even finer bead size ranges (01 05 mm) (Figure 1) Milling Actions Grinding, or deagglomeration, is affected by impact, pressure and shear forces between the grinding media and the mill partsJun 18, 2014 Roll Pass Design satyendra; June 18, 2014; 1 Comment ; Long products, roll grooves, Roll pass, Roll pass design, rolling mill, rolls, sections,; Roll Pass Design Long products are normally rolled in several passes, whose numbers are determined by the ratio of the initial input steel material (square or round billet or bloom) and final cross section of finished productRoll Pass Design – IspatGuruMachine size K0 K1 K2 K2A K4 K5 K6 K6A K7 K8 K10 NR2 rotors 164 5 18 44 82 126 185 231 330 436 783 NR5 rotors 182 55 20 49 91 140 205 257 330 484 870TECHNICAL RUBBER COURSEindeed lead to finer products and thinner flakes, but will reduce capacity and wear out faster Horsepower and Machine Size Double Pair Roller Mills Roller Mill Size Low High 90024 20 40 90036 40 60 120024 40 60 120036 60 100 120052 75 150 120072 100 200 Roll Life and Materials Processed Easy to process / Long life Corn, 48% Soybean MealRoller Mill Maintenance00 CPMEffect of circulating load and classification efficiency on HPGR and ball mill capacity October 2014 the edge bypass effect that increases the product size High pressure grinding roll (PDF) Effect of circulating load and classification

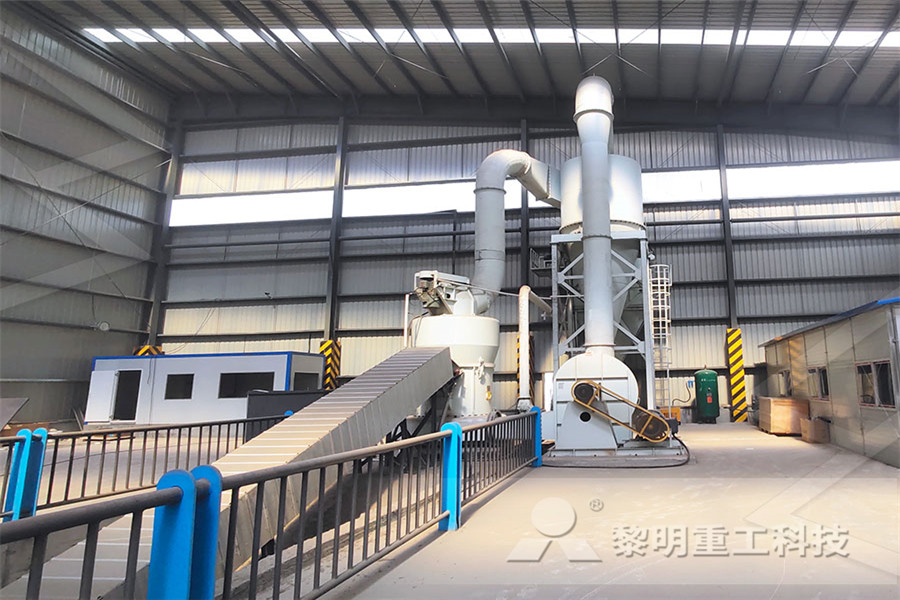

Load Analysis and Driven Power Calculation (4 Roll Bending

D a – Upper roll diameter; D c – Side roll diameter; γ – Tilt Angle of the side roll, which is the angle between the adjustment direction of the side roller and the vertical direction; A – The distance from the intersection point of the roll angle to the center of the upper roller 222 The rollers are arranged in an asymmetrical mannerHC1700 grinding mill is a better choice for large scale powdermaking projects It effectively increases the production capacity while reducing the power consumption Compared to the traditional mill (5R Raymond mill), the capacity of HC1700 grinding mill is about 25 to 4 times higherHC1700 Grinding Mill, Raymond Roller Mill, Pendulum Roller