Case

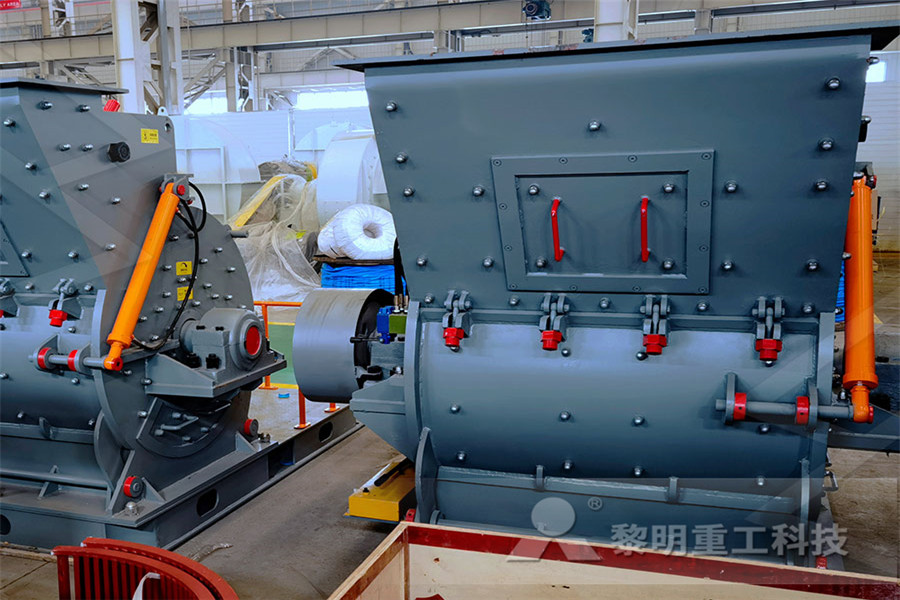

primary crushing crusher

2020-11-17T09:11:11+00:00

Primary Crusher an overview ScienceDirect Topics

The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbeltsFeb 26, 2016 The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this service are much the same, regardless of how many Primary Crushing Mineral Processing MetallurgyHome Machinery Crushing and Grinding Steele Primary Crushers Steele Primary Crushers — Costeffective, reliable sizing for bulk raw materials Robust, workhorse machines built for decades of reliable sizing and consistent output, with minimal maintenance, easy wear part replacement and fast change outs for drives and roll speedsSteele Primary Crushers Steele Machinery JC Steele Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a jobWhat Is Primary, Secondary, and Tertiary Crushing?How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Primary Crusher Selection Design

Primary Impact Crushers MEKA Crushing Screening Plants

PRIMARY IMPACT CRUSHER Primary Impact Crushers are preferred for their high capacity and reduction ratios in crushing soft and medium hard rocks like limestone, gypsum Due to their operating principle, reduction ratio is higher than in jaw crushers HIGH QUALITY FINES PRODUCTIONPrimary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The common primary crushers are of jaw and gyratory typesCrusher an overview ScienceDirect Topics8 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucksConstruction, Working and Maintenance of Crushers for Primary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be usedRock Crusher Eastman Rock CrusherFrom large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Outotec equipment is manufactured to meet your material reduction requirements The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and Crushing Outotec

Steele Primary Crushers Steele Machinery JC Steele

Home Machinery Crushing and Grinding Steele Primary Crushers Steele Primary Crushers — Costeffective, reliable sizing for bulk raw materials Robust, workhorse machines built for decades of reliable sizing and consistent output, with minimal Dec 17, 2020 Primary crushing is for the robust The very first crushers invented were jaw crushers, which are built to reduce the size of large materials and operate with high volume in primary crushing Their main purpose is to reduce the material to a small enough size that it can be transported to the next crushing stage by conveyors Jaw crushers can Crushing 101 – Different types of crushers for distinctive Primary Impact Crushers are preferred for their high capacity and reduction ratios in crushing soft and medium hard rocks like limestone, gypsum Due to their operating principle, reduction ratio is higher than in jaw crushersPrimary Impact Crushers MEKA Crushing Screening PlantsCrushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m sizeCrusher an overview ScienceDirect TopicsJaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate JXSC

Primary Jaw Crushers Moore Watson Ltd

The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing applications of hard abrasive rock or recycling material It is suitable for large and small stationary installations or track and mobile units The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty nonwelded side frames connected to high quality machined Built in America, we’re a new kind of crushing company with the same values your grandpa depended on to crush rock! Liberty ® Jaw Crusher Primary Maximum Feed Size 47″ (1,194mm) Product Size 15″ – 5″ (380mm – 125mm) Maximum Reduction Ratio 6:1 Maximum Production Rate 1,595 STPH (1,446 MTPH) Crushing Equipment Superior Industries US Manufacturer8 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucksConstruction, Working and Maintenance of Crushers for Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types 2 Secondary CrushingRock Crushers Crushing Equipment Kemper Equipmentboulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher Jaw, impactor, or gyratory crushers are usually used for initial reduction The crusher product, normally 75 to 30 centimeters (3 to 12 inches) in diameter, and the grizzlyAP42 Section 11192 Crushed Stone Processing and

Different types of crushing equipments Constro Facilitator

The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material) Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher After receiving the primary crusher crush the material and produce a new fresh reduced size of the source material This is a video compilation of 9 different Verdés Primary Crushers for clay and mineral crushingPrimary crushers are suitable for the primary crushing or grVERDÉS® Primary Crushers for clay and Mineral Crushing Sandvik QI441 mobile impact crusher is a pioneering solution offering primary and secondary crushing in one unit Maximum productivity and efficiency in a single investmentThis mobile impact crusher Primary crusher, Primary crushing plant All industrial Sep 02, 2019 Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary Breaking Home Machinery Crushing and Grinding Steele Primary Crushers Steele Primary Crushers — Costeffective, reliable sizing for bulk raw materials Robust, workhorse machines built for decades of reliable sizing and consistent output, with minimal Steele Primary Crushers Steele Machinery JC Steele

Primary Impact Crushers MEKA Crushing Screening Plants

Primary Impact Crushers are preferred for their high capacity and reduction ratios in crushing soft and medium hard rocks like limestone, gypsum Due to their operating principle, reduction ratio is higher than in jaw crushersPrimary crushing reduces the large pieces to a size which can be handled by the downstream machinery Some crushers are mobile and can crush rocks as large as 15 meter (60 inches) Primarily used inpit at the mine face these units are able to move Crusher WikipediaOct 17, 2019 When choosing the best crusher for your primary, you first have to consider the application details Desired product size, capacity, HGI, percentage of rock, and hardness of the rock in the feed are some of the factors that dictate the selection of primary crushing equipmentHow Do I Know Which Primary Crusher Is Best For Mineral 8 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucksConstruction, Working and Maintenance of Crushers for The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material) Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher After receiving the primary crusher crush the material and produce a new fresh reduced size of the source material Different types of crushing equipments Constro Facilitator

Rock Crushers Crushing Equipment Kemper Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types 2 Secondary CrushingSep 02, 2019 Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary Breaking Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher Eastman Rock Crusherboulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher Jaw, impactor, or gyratory crushers are usually used for initial reduction The crusher product, normally 75 to 30 centimeters (3 to 12 inches) in diameter, and the grizzlyAP42 Section 11192 Crushed Stone Processing and Apr 03, 2015 Types of crushers Crushers are classified into three types based upon the stage of crushing they accomplish These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in sizeCrushers and Their Types – IspatGuru

Primary Mining Quarry Rock Small Portable Jaw Crusher of

As a classic primary crusher with stable performances, PE Jaw Crusher is widely used to crush metallic and nonmetallic ores as well as building aggregates or to make artificial sand It is mainly used as primary crushing machine to crush soft rock, hardrock, and mineral oresThe jaw crusher is the first stage in the crushing and screening process, the main purpose of this stage is to crush the rock into a conveyable size In addition to this, other tasks are also performed such as: With this in mind the design of the primary jaw crusher stage is more than just getting the blasted material into the jaw crusher Designing a Crushing Screening Plant – Part I Primary More efficient than primary gyratory crushers Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit Types of Jaw Crushers Jaw crushers have been around for nearly 200 years at this point and How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment