Case

weight feeders of clinker

2022-04-06T23:04:29+00:00

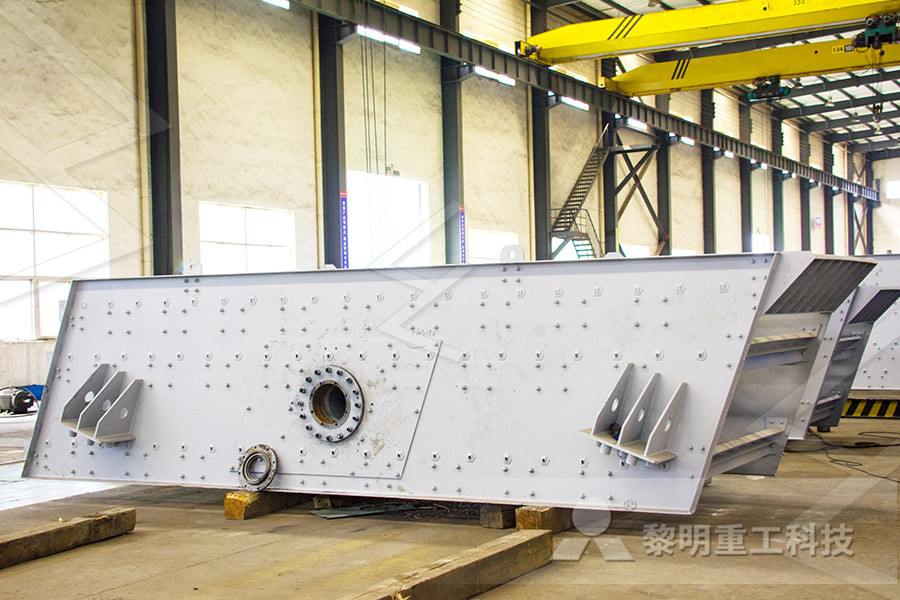

APRON WEIGH FEEDER zasagencies

† Clinker † Granulated blast furnace slag † Petroleum coke The deepdrawn pan version of the AUMUND Weigh Feeder is recommended, for example, whenever proportional feeding of clinker into the cement mill is required For mill feeding either on the raw material or the cement side, the Weigh Feeder is also available as enclosed and pressure Apron extractor Weigh feeders are used for difficult products to extract, in the ore crushing workshop or for coke ovens HASLER Group’s range of equipment allow the flow measurement and dosing of raw materials such as pellets, clinker and limestone or coal Dosage, Agitation, Filtration, Processing Cement process(d) The quantity of clinker produced monthly by each kiln must be determined by direct weight measurement of clinker using the same plant techniques used for accounting purposes, such as reconciling weigh hopper or belt weigh feeder measurements against inventory measurements40 CFR § 9884 Monitoring and QA/QC requirements Code of Providing accuracy guarantees on its calibration services and weighing equipment, with 30 years of market leading innovation Control Systems Technology, for when accuracy matters! Calibration, Service and Repair Of All Weighing Equipment All types of weigher servicing, repairs, calibrations and trade certifications LEARN MORE CST Belt Scales and Weigh Feeders Market leader in Conveyor Belt Weigh Feeders Control SystemsDec 06, 2016 The size of clinker for liter weight is between 5 10 mm A clinker of density approximately 1100 g/ltr is of normal quality, but below than that is not considered a good quality clinker, and if it is above 1300 g/ltr it can be over burned or over fueled How To Find Liter Weight Of ClinkerStanding Procedure For Liter Weight of Cement Clinker

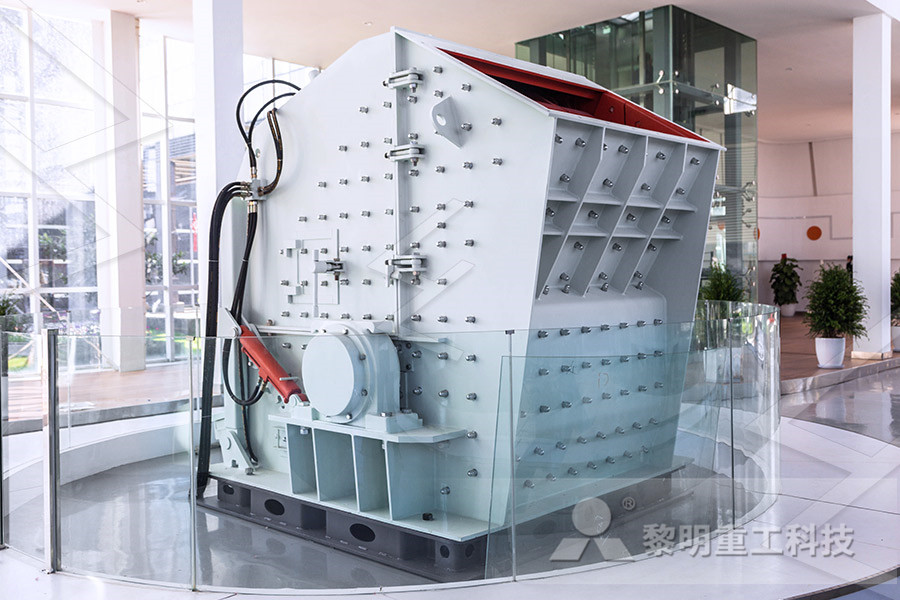

What is Cement Clinker? Composition, Types Uses Civil

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln The Models 402 and 404 Series, and the Models 405, 406, and 408 ' WeightLoss' Weigh Feeders feature a Platform type weighing system specifically designed by Acrison for continuous or batch weighing of dry solids or liquids on a weightloss basisWeigh Feeders AcrisonFeb 02, 2015 Clinker litre weight Dear all, My kiln capacity is 4500 TPD, but we are operating it at 5400 TPD My problem is clinker litre weights are higher side ie > 1270 g But I want to maintaine around 1200 g Can any body suggest me is there any way to reduce the clinker litre weights by changing the raw mix design, if so request you to share the Clinker litre weight Page 1 of 3feeding, requiring a weight feeder of high accuracy Clinker is mainly composed of four mineral phases: Tricalcium silicate (3CaO ∙ SiO 2 or C 3 S), dicalcium silicate (2CaO ∙ SiO 2 or C 2 S), tricalcium aluminate (3CaO ∙ Al 2 O 3 or C 3 A) and tetracalcium aluminoferrite (4CaO ∙ Al 2 28 Simulation of Cement Grinding Process for Optimal Clinker Bin Scale: 170 t Task: Components feeding in Cement mill according receipt Cement mill feeding control Onstream calibration Solution: 4 Weight Feeders, 1 Belt Scale of returns, Bin Scales, Electrical ear and mill feeding control system were delivered and installed Weigh Feeders were installed directly under the binsFeeding system into the cement mills with stream

Sharrcem

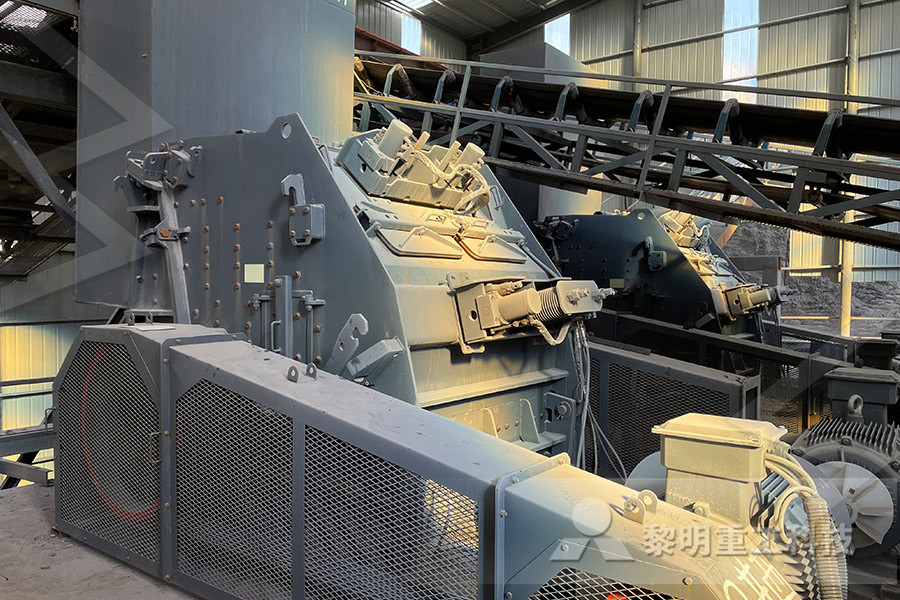

operate from the Rotary Weight Feeders (Kiln Feed) to the Clinker Transport, while the Cement Mill Operator’s part starts from the Weight Feeders of Clinker and Additives to the Cement Silos The remote management, enabled through the KHDPRODUX software, provides fast andMakalah ini menjelaskan tentang pemodelan dan simulasi sistem fisik yaitu weight feeder clinker yang ada di Finish Mill area II41 PT Semen Gresik (Persero), Tbk Setelah model matematika tiap Pemodelan dan Simulasi Weight Feeder Clinker Di Finish Providing accuracy guarantees on its calibration services and weighing equipment, with 30 years of market leading innovation Control Systems Technology, for when accuracy matters! Calibration, Service and Repair Of All Weighing Equipment All types of weigher servicing, repairs, calibrations and trade certifications LEARN MORE CST Belt Scales and Weigh Feeders Market leader in Conveyor Belt Weigh Feeders Control SystemsModel 400 Series Weight–Loss Weigh Feeders Overview Acrison’s various Model 400 Series of Weigh Feeders operate on a WeightLossDifferential (or lossinweight feeding) basis; they are designed with an integral Acrison dry solids feeder, or a positive displacement liquid pump, as the metering mechanism of these precision alldigital weigh feeders, precisely controlled by an Acrison Weigh Feeders AcrisonCombustion equipment and combustion systems manufacturer for industrial,municipal,cogeneration independent power producers (IPPs)Detroit Stoker Ash Handling Systems Clinker Grinder

Clinker litre weight Page 1 of 3

Feb 02, 2015 Clinker litre weight Dear all, My kiln capacity is 4500 TPD, but we are operating it at 5400 TPD My problem is clinker litre weights are higher side ie > 1270 g But I want to maintaine around 1200 g Can any body suggest me is there any way to reduce the clinker litre weights by changing the raw mix design, if so request you to share the Lossinweight feeders Lossinweight feeders are genuine allrounders and have replaced many volumetric and gravimetric feeders since the 1980s Lossinweight feeders can be used for both small to medium feeding ranges They work with extreme precision under optimum ambient conditionsLossinweight feeders Schenck ProcessLoss In Weight Feeder LIWF are feeders which are able to measure their change of weight over time and control it The feeder is made of a hopper and of a dosing instrument that can be a single screw, a double screw , a vibrating tube or a belt for the most common modelsLoss In Weight Feeders Continuous dosing of powder and Clinker Storage Feeders Vibroflow Dec 12 2018 The inlet of the feeder is sealed completely with a rubber gasket The discharge has a rubber curtain installed so that dust pollution is minimised Bisalloy wear liners have been installed on all material contact surfaces Close up top Clinker cement vibrating feeders Vibrating feeder Read MorePune vibration feeder processing cement clinkerAbout Cement, clinker; 1 415 kilograms [kg] of Cement, clinker fit into 1 cubic meter; 8833556 pounds [lbs] of Cement, clinker fit into 1 cubic foot; Cement, clinker weighs 1415 gram per cubic centimeter or 1 415 kilogram per cubic meter, ie density of cement, clinker is equal to 1 415 kg/m³In Imperial or US customary measurement system, the density is equal to 883356 pound per cubic Cement, clinker weight to volume conversion

Gujarat vibration feeder processing cement clinker

Clinker Feeders Vibroflow Dec 12 2018 Both feeders are suspended via ropes and steel coil isolating springs Two 035kw motors excite these feeders to achieve a feed rate of 150tph of clinker cement Clinker vibrating feeders packaged for dispatch Rendering of clinker vibrating feeder Read Morefeeder weight Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor Peeters Martin Original Assignee Peeters MartinUSA Constant weight feeder Google Patents2 BELT WEIGH FEEDERS (EXISTING) For clinker and gypsum Type of feeder : Belt weigh feeder Control range : 10: 1 Feed material : Clinker Gypsum Capacity (Requirement) Clinker TPH : 25250 Gypsum TPH : 2525 Accuracy % : + 10% of full scale 721 BC1TECHNICAL SPECIFICATIONS† Clinker † Granulated blast furnace slag † Petroleum coke The deepdrawn pan version of the AUMUND Weigh Feeder is recommended, for example, whenever proportional feeding of clinker into the cement mill is required For mill feeding either on the raw material or the cement side, the Weigh Feeder is also available as enclosed and pressure APRON WEIGH FEEDER zasagenciesquality is the variability of the clinker activity [1] which depends on the conditions of the clinker formation, raw meal composition and fineness A stable raw meal grinding process provides a low adjustment of the mill weight feeders according to the raw meal chemical modules in the RM outletModeling of Raw Material Mixing Process in Raw Meal

Effective Optimization of the Control System for the

depending on the conditions of the clinker formation and the raw meal composition In Figure 1 a typical flow chart of raw meal production is shown Figure 1 Flow chart of raw meal production In the closed circuit process demonstrated, the raw materials’ feeding is performed via three weight feeders, firstly feeding a crusherfeeders is identical: Material is extracted out of the material silo and is transported in the rotor chambers (1) from the inlet (2) to the outlet (3) The rotor is mounted on bearings which form a weighing axis (AA) This axis (AA) is eccentric to the rotor cement clinker is fed into a roller mill circuit byProduct Brochure Pfister TRW / TRWKMakalah ini menjelaskan tentang pemodelan dan simulasi sistem fisik yaitu weight feeder clinker yang ada di Finish Mill area II41 PT Semen Gresik (Persero), Tbk Setelah model matematika tiap Pemodelan dan Simulasi Weight Feeder Clinker Di Finish (d) The quantity of clinker produced monthly by each kiln must be determined by direct weight measurement of clinker using the same plant techniques used for accounting purposes, such as reconciling weigh hopper or belt weigh feeder measurements against inventory measurements40 CFR § 9884 Monitoring and QA/QC requirements Code of Clinker Feeders Vibroflow Dec 12 2018 Both feeders are suspended via ropes and steel coil isolating springs Two 035kw motors excite these feeders to achieve a feed rate of 150tph of clinker cement Clinker vibrating feeders packaged for dispatch Rendering of clinker vibrating feeder Read MoreGujarat vibration feeder processing cement clinker

Pune vibration feeder processing cement clinker

Clinker Storage Feeders Vibroflow Dec 12 2018 The inlet of the feeder is sealed completely with a rubber gasket The discharge has a rubber curtain installed so that dust pollution is minimised Bisalloy wear liners have been installed on all material contact surfaces Close up top Clinker cement vibrating feeders Vibrating feeder Read MoreFeb 02, 2015 Clinker litre weight Dear all, My kiln capacity is 4500 TPD, but we are operating it at 5400 TPD My problem is clinker litre weights are higher side ie > 1270 g But I want to maintaine around 1200 g Can any body suggest me is there any way to reduce the clinker litre weights by changing the raw mix design, if so request you to share the Clinker litre weight Page 1 of 3additives like fly ash, clinker, gypsum, limestone, and additive slag feed by the weigh feeder Weigh feeder is the belt conveyor which used to control the flow rate of the additive materials The clinker comes from the kiln at hot condition is about 100°C or above Where the slagMODIFIED CHUTE DESIGN FOR SLAG REMOVAL IN May 11, 2008 Clinker High Liter Weight and High Free Lime Our kiln is normally produce clinker of minmum liter weight of 1350 up to 1400 and free lime ~ 1 % if We tried to decrease liter weight to 1250 gm/lt free lime get more than 2% Any one could help for diagnosis of this phenomena Clinker High Liter Weight and High Free Lime Page 1 of 5The MAMMUTHUS CLINKER is a device used both as a strong apron feeder and as a common weigh belt feeder The speed is controlled according to the material load in order to obtain a constant and accurate flowrate The load is measured by two digital load cells (integrated weighbridge) through the Apron feeder end weigh belt feeder Mammuthus Clinker

Export Data and Price of cement clinker Zauba

View detailed Export data, price, monthly trends, major exporting countries, major ports of cement clinker