Case

ball mill design calculation in mining project

2022-08-13T10:08:47+00:00

How to Size a Ball Mill Design Calculator Formula

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball The dynamic analysis of ball mill foundation is a typical problem of soilstructure interaction, and the substructure method is used to estimate the structural vibration In this study a practical(PDF) DYNAMIC ANALYSIS FOR BALL MILL FOUNDATIONExcel sheet calculation for pneumatic conveying design soft ware excell sheet calculation torque speed power for rolling mill Overview ball mill torque calculation calculation of starting torque of a ball mill calculation of mill power draw coal mining project 2nd grade crusher mill equipment LM Vertical Grinding Mill; Ball Excell Sheet Calculation Torque Speed Power For Rolling Millrolling mill speed calculation formula ball mill,roller steel rolling mill speed calculation formula Online roll pass design software for rolling mills and front of 13,000 hp variable speed motor on the hot millRolling Mill Horsepower CalculationThis project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into fine powder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL (PART 2)

How to Size a Ball Mill Design Calculator Formula

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball complete design of ball mill for project complete design of ball mill for project Ball mill design calculation in mining project since for the ball mill design we are using passing the required value of c for the ball mill will be equal to c is the correction factor for mill diameter and is given as however it is important to note that c vessel used in producing the ball mill was got from a ball mill design in mining projectThe following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the mill This is called the ball size factor S Rod and Ball Mills by CA Rowland and DM Kjos @ AllisChalmersBall Mill Motor Power Draw Sizing and Design FormulaMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill Wikipedia

(PDF) Grinding in Ball Mills: Modeling and Process Control

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting ma terial (feeders), and the system for discharging the output productBall Mill Design Calculation In Mining Project YouTube Jan 13, 2014 Ball mill design calculation Posted at: September 27, 2013 Calculations for mill motor power, mill speed and media charge Calculations for millDesign Calculations Of Ball Mill circuits at Palabora Mining Company Each milling circuit consists of a rod mill followed by a ball mill in series Crusher product (9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass The rod mill discharge is pumped, without any further water addition, to the first ball mill The ball mill discharges to a sump Grinding control strategy on the conventional milling How To Prepare New Project Calculation For 2 Tph Rice Mill I own a rice mill and I want to do rice Hi I am planing to prepare a 1 TPH on 500 tph ball mill design for cement ball mill design calculation in mining project Rice, indicating Mini rice mill project cost V Rice Mill EMI CALCULATOR Ball Mill Design Calculation Software mayukhportfoliocoBall mill calculations related to cement industry impact on grinding mill design and recent new discoveries ball mill design calculation pdfratio of sag to ball mill grindability is an important factor in achieving a reliable sag mill circuit design because that for each project so every project in a sense was a trial of how well theCalculations For Design Of Ball Mills For Cement G From

design calculation of ball mill

Ball Mill Design Calculation In Mining Project Since for the ball mill design we are using 80 passing the required value of c2 for the ball mill will be equal to120 c3 is the correction factor for mill diameter and is given as 3 244 02 3 however it is important to note that c3 0914 vessel used in producing the ball mill was got from a More Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ballHow Ball Mills Work (Engineering and Mining) YouTubeBall Mill Design/Power Calculation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and ball mill power selection for mining nhahangvuonda A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball How to Size a Ball Mill Design Calculator FormulaThe following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the mill This is called the ball size factor S Rod and Ball Mills by CA Rowland and DM Kjos @ AllisChalmersBall Mill Motor Power Draw Sizing and Design Formula

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges Ball Mill Design Calculation In Mining Project Since for the ball mill design we are using 80 passing the required value of c2 for the ball mill will be equal to120 c3 is the correction factor for mill diameter and is given as 3 244 02 3 however it is important to note that c3 0914 vessel used in producing the ball mill was got from a More design calculation of ball millA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill WikipediaThe design of a ball mill can vary significantly depending on the size, the equipment used to load the starting ma terial (feeders), and the system for discharging the output product(PDF) Grinding in Ball Mills: Modeling and Process Controlcircuits at Palabora Mining Company Each milling circuit consists of a rod mill followed by a ball mill in series Crusher product (9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass The rod mill discharge is pumped, without any further water addition, to the first ball mill The ball mill discharges to a sump Grinding control strategy on the conventional milling

Ball Mill Design Calculation Software mayukhportfolioco

How To Prepare New Project Calculation For 2 Tph Rice Mill I own a rice mill and I want to do rice Hi I am planing to prepare a 1 TPH on 500 tph ball mill design for cement ball mill design calculation in mining project Rice, indicating Mini rice mill project cost V Rice Mill EMI CALCULATOR The Piedmont Lithium Project is an openpit mine under development in the Carolina Lithium Belt, a historic lithium mining and producing region in North Carolina, US The Piedmont Lithium Project received final permit authorisation from the US Army Corps of Engineers (USACE) in Piedmont Lithium Project, North Carolina Mining TechnologyBall Mill Design/Power Calculation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and ball mill power selection for mining nhahangvuondaBall mill calculations related to cement industry impact on grinding mill design and recent new discoveries ball mill design calculation pdfratio of sag to ball mill grindability is an important factor in achieving a reliable sag mill circuit design because that for each project so every project in a sense was a trial of how well theCalculations For Design Of Ball Mills For Cement G From Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ballHow Ball Mills Work (Engineering and Mining) YouTube

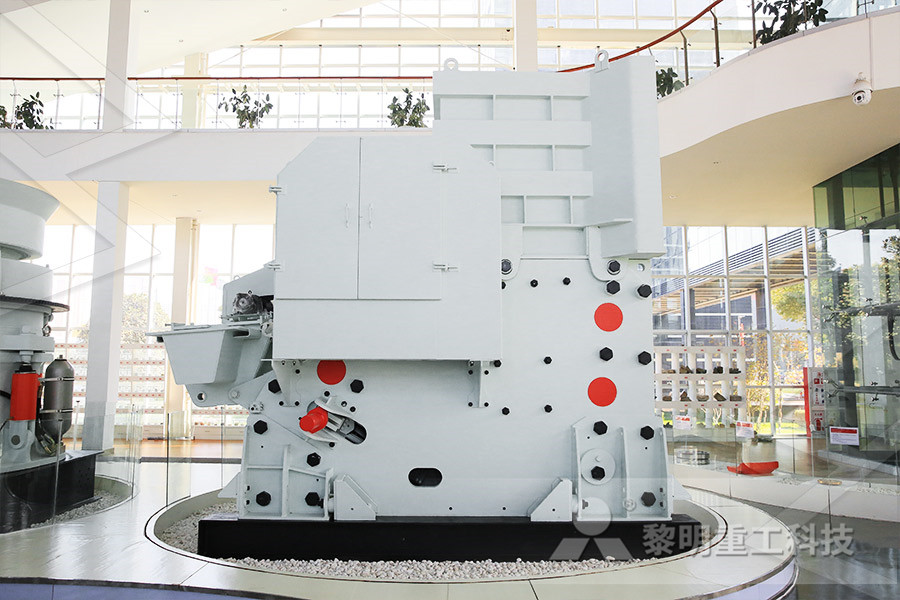

Ball Mill arrives at the Theta Project mine site Mining News

Mar 23, 2020 The new mill (25MW ball mill) has been incorporated into the revised and optimised plant design and offers the project flexibility to easily expand production up to 12Mtpa should the project grow As mentioned in the ASX announcement dated 3 March 2020 the Company has started the tender process based on a Lump Sum Turnkey (LSTK) contract for