Case

Low Power Consumption Mobile Roll Crusher Application Analysis

2023-09-04T20:09:19+00:00

Application of the rollercrusher principle to processing

Fig* ij6 Plot of sieve analysis of precrushed corncobs processed by th© Knoedler mill 155 Fig J47 Plot of sieve analysis of precrushed corncobs processed by the Knoedler mill 156 Pig, I48 Plot of sieve analysis of whol© corncobs processed by th© Letz mill I6I Fig i9 Plot of si@v® analysis High speed roll crusher Low speed sizer Impactors Low fines production Low power consumption Easy rejection of oversize feed – using discharge gates The tests operated at a fixed tonnage were conducted to simulate a crushing application where the crusher is not the limiting equipment therefore the tonnage to the crusher is fixed Crushing / Screening and ConveyingMetallurgical ContentCrushing Screening Plant Assessment ExampleCapacities and Horsepower of Jaw Crushers (tons/hr)Typical Capacities of TwinRoll Crushers (tons/hr)Screen Analysis of Product from Jaw Crusher, Percent Passing Screen Opening The following example demonstrates a method of selecting the components of an aggregate plant Good component efficiency and part performance pre Crusher Efficiency CalculationsFigure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusher Such circuits are chosen as the feed size to standard roll crushers Roll Crusher an overview ScienceDirect TopicsLow cost of operation investment; The total weight of the counterattacking crusher is lighter than that of the hammer crusher, the shape size is small, and the dynamic load value is low, which can effectively reduce the civil cost Low motor power required can effectively Analysis of Advantages and Disadvantages of Impact Crusher

Power Law Model for Reliability Analysis of Crusher System

Analysis of the effect of this strategy indicated 16 times improving efficiency of the fixed capital KEYWORDS: Crusher system, Maintenance, Reliability, Time between failures, Power law model 1 INTRODUCTION One of the most important and inseparable stages of mineral processing in various fields and industries is crushing materialsRoll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers can adjust the wedge device between rollers to control the feed and discharge size of the machineRoll Crusher With stable Performance Fote Machinery(FTM)Apr 24, 2015 CAPACITY OF ROLL CRUSHER The capacity of a roll crusher will vary with: The kind of stone The size of feed The size of the finished product The width of rolls The speed at which the rolls rotate The extent to which the stone is fed uniformly into the crusher 13 POWER CONSUMPTION OF ROLL CRUSHERS WITHIN THE SAME REDUCTION RATIO POWER Roll crushers SlideShareJun 12, 2014 The roller crusher can do secondary and fine crushing of materials with middle hardness or middle minus hardness, such as mineral, rocks, coke, coal, slag, scoria, and fireproof material, etc Features of Oriental Roller Crusher low energy consumption; adjustable space between rollers of the crusher, thus improving the capacity; the movable Double roll crushers mabufacturers SlideShareThe new crusher features a particularly flat and robust design and high throughputs of up to 3000 t/h, enabling it to process hard rock and ores efficiently and economically in underground mining operations As the centerpiece of a mobile or semimobile system the eccentric roll crusher also enhances cost efficiency in surface miningNew crusher revolutionizes material processing in both

Stationary VSI impact crushers, Sandvik VSI Crusher

Sandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption The autogenous "rock on rock" crushing technique results in several major advantages: Product gradation remains constant, contamination rates are extremely low, and it has announced the sale of a Roll Crusher HRC 0810 (565 t/h) for kiln stone production in a magnesite ore application in Brazil The hydraulic retraction and gap adjustment system will work in tandem with an optical onbelt particle size analyser and allow adjustment of the crusher gap setting to compensate for wear Roll Crusher set for magnesite application in A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipediaanother critical application factor to note is the effect of contaminated material like the jaw crusher the cone crusher provides a relatively low cost crushing Know More 10 factors to consider when choosing a crushing equipmentimpact crusher factorsAutoMine® for Trucks turns Sandvik’s intelligent mining trucks into unmanned robots that just keep running Now including new functions such as OptiMine® connectivity, upgraded Access Control System for greater flexibility, and the ability to extend the truck fleet’s autonomous production cycles from underground to surface tipping; they are safer, more efficient with a lower cost per tonSandvik Mining and Rock Technology — Mining Equipment

municipal solid waste recycling plant manufacturer (msw

Duromech Mobile Crushing Plant with conveyor systems are the most economical alternative to the orthodox system of crushing and truck transport in a mine Bucket Elevator The Bucket Elevator stands out due to its high degree of durability, safety features and low power consumption in Our business is built around a simple but powerful idea: Performance in every detail We’re dedicated to delivering bestinclass results for all our customers, so we design every Keestrack product from the ground up to be highly efficient and cost effective, with many Keestrack Flow Control has become a separately listed independent company called Neles Neles is a flow control solutions and services provider for oil and gas refining, pulp, paper and the bioproducts industry, chemicals, and other process industries global website A 4B customer was struggling with their drag chain conveyors transporting a corrosive byproduct of crude oil processing The chain was breaking and wearing fast, causing much downtime and productiontime loss due to the repairs required on the conveyors 4B resolved the problem with heavy duty linkbulkonline Home of the powder bulk solids Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between Rock Crushing Rule of Thumb Mineral Processing Metallurgy

Jaw Crushers high quality and reliability from RETSCH

Applications Details Jaw crushers are always at the very front of the sample preparation chain, precrushing all hard and brittle materials They are primarily used in laboratories and pilot plants under rough conditions but are also suitable for online quality control of raw materialsThe unit power consumption is low and it has fewer requirements for the crushed materials' humidity requirements It is also suitable for any hard brittle materials or other various kinds of minerals Through large engineering, the small rock crusher shows that it has good application prospect in the field of mineral processing equipmentSmall Rock Crusher for Sale, Mini Stone Crushing Machine DELUMPER® S4 Crushers feature precision operation, easy interior access, cleaninplace capability, and a meticulously polished finish A convenient side door provides fast and easy access to the interior of the cutting chamber for maintenance The S4 employs a direct gear drive for smooth and quiet operation as well as low maintenancePremium Crushers and Lump Breakers Franklin Miller Incemission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section 11192, "Crushed Stone Processing" In the absence of other data, the emission factors presented in Section 11192 can be used to estimate emissions from corresponding sand and gravel processing sources11191 Sand And Gravel ProcessingMetallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between Rock Crushing Rule of Thumb Mineral Processing Metallurgy

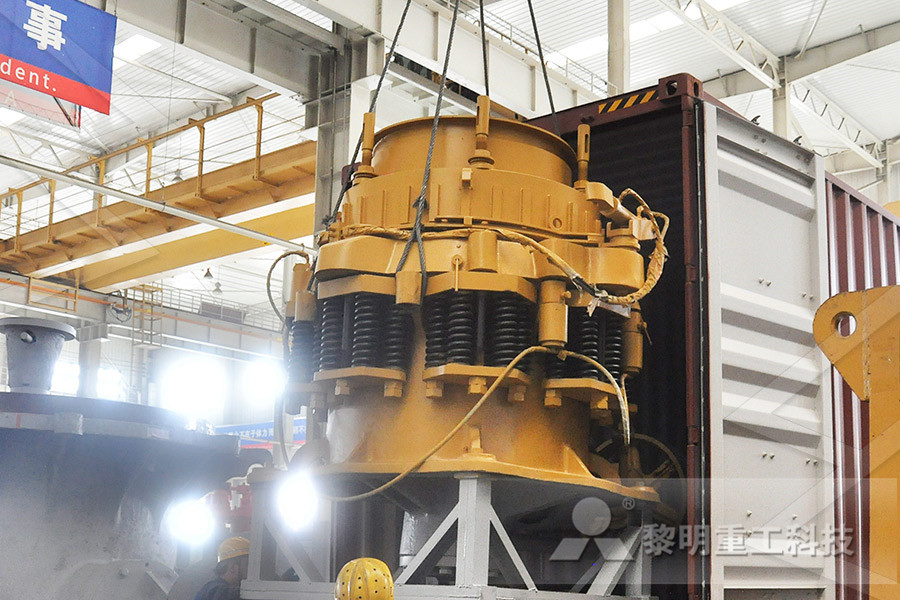

Turning things to your advantage: Kubria Cone Crushers now

The crusher shaft is guided by the eccentric bushing insert (4) and moved in a tumbling motion The stroke of the tumbling motion is determined by the eccentric insert The stroke influences not only the quality of the final product, but also the throughput rate and power consumption of the cone crusherThe unit power consumption is low and it has fewer requirements for the crushed materials' humidity requirements It is also suitable for any hard brittle materials or other various kinds of minerals Through large engineering, the small rock crusher shows that it has good application prospect in the field of mineral processing equipmentSmall Rock Crusher for Sale, Mini Stone Crushing Machine Our business is built around a simple but powerful idea: Performance in every detail We’re dedicated to delivering bestinclass results for all our customers, so we design every Keestrack product from the ground up to be highly efficient and cost effective, with many Keestrackanother critical application factor to note is the effect of contaminated material like the jaw crusher the cone crusher provides a relatively low cost crushing Know More 10 factors to consider when choosing a crushing equipmentimpact crusher factorsA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

LowDropout Regulators Analog Devices

Ask The Applications Engineer—37: LowDropout Regulators by Jerome Patoux Download PDF This article introduces the basic topologies and suggests good practical usage for ensuring stable operation of lowdropout voltage regulators (LDOs) We will also discuss design characteristics of Analog Devices families of LDOs, which offer a flexible approach to maintaining dynamic and dc stability Flow Control has become a separately listed independent company called Neles Neles is a flow control solutions and services provider for oil and gas refining, pulp, paper and the bioproducts industry, chemicals, and other process industries global website A 4B customer was struggling with their drag chain conveyors transporting a corrosive byproduct of crude oil processing The chain was breaking and wearing fast, causing much downtime and productiontime loss due to the repairs required on the conveyors 4B resolved the problem with heavy duty linkbulkonline Home of the powder bulk solids Product Brief: Specifications of multifunctional wood crusher ; 1easy operating and low power consumption; 2high quality and unique design 3multifunctional Crusher sourcing, purchasing, procurement agent service William’s Single and Double Roll Crushers are simple in design and construction, longlasting, economical, and versatile Roll Crushers are more suitable for smaller industrial applications and are also available in a 15inch (381mm) diameter dusttight version for glass crushing applications where it would be expensive to have dust Glass Crushers Glass Crushing Machines Williams Crusher

Low Power Wide Area Network Market Size Share Trends

Low Power Wide Area Network Market Size And Forecast Low Power Wide Area Network Market was valued at USD 807 Billion in 2019 and is projected to reach USD 102878 Billion by 2027, growing at a CAGR of 9001% from 2020 to 2027 The major factor driving the growth of low power wide area network is the increase in adoption of machine to machine communication and minimized cost 6LoWPAN is an acronym of IPv6 over Low Power Wireless Personal Area Networks 6LoWPAN is the name of a concluded working group in the Internet area of the IETF The 6LoWPAN concept originated from the idea that "the Internet Protocol could and should be applied even to the smallest devices," and that lowpower devices with limited processing capabilities should be able to participate in the 6LoWPAN Wikipedia