Case

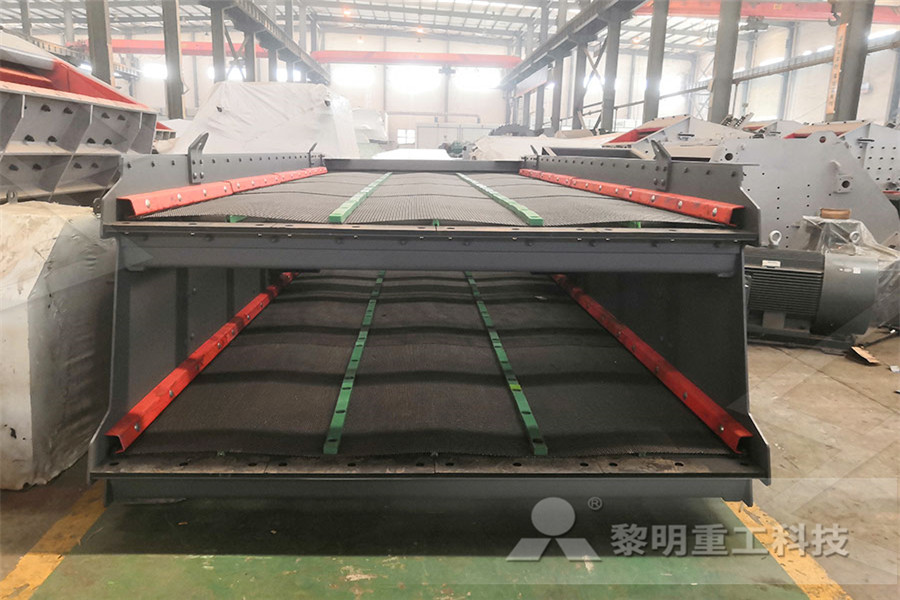

internal view of ball mill

2022-10-17T23:10:14+00:00

Ball Mills an overview ScienceDirect Topics

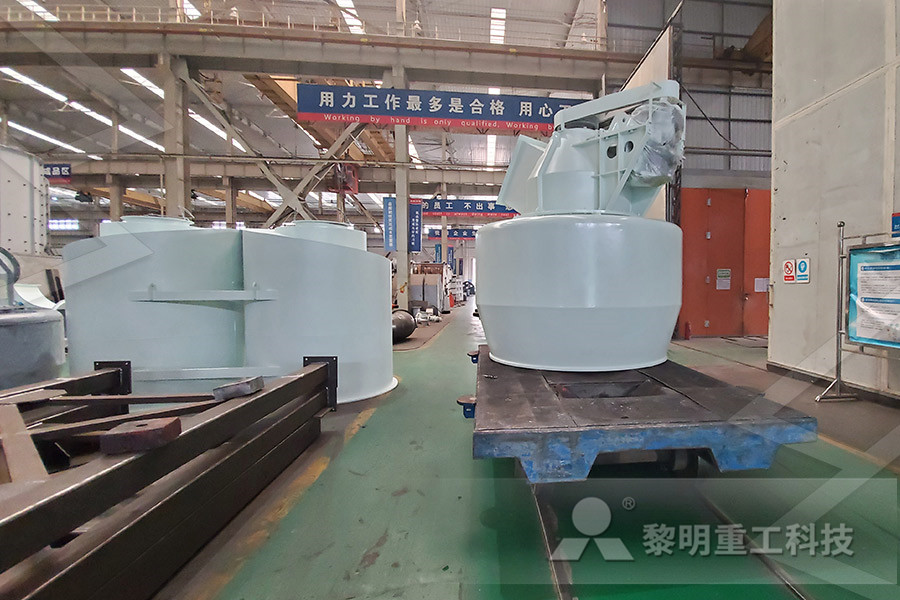

Ball mill external appearance and internal view Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fractureJan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses the collision energies in the mill Yashima et al (1988) and Nomura et al (1991) estimated the sizedependent rates of breakage of particles contained in ball mills using singleparticle slow compression data and experimental measurements of impact energy spectra using load sensors positioned in the shell of a lab mill, showing someA Review of Advanced Ball Mill ModellingIf a ball mill contained only coarse particles, then 100% of the mill grinding volume and power draw would be applied to the grinding of coarse particles In reality, the mill always contains fines: these fines are present in the ball mill feed and are produced as the particles pass through the millMODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLINGA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill Ball mill Wikipedia

Ball Mills an overview ScienceDirect Topics

Ball mill external appearance and internal view Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the ballsSep 01, 2020 Ball Mill detail overview Working principle Internal External part description Water injection systemMr JK Singh (Whattapp: ) has experienBall Mill detail overview Working principle Internal A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses the collision energies in the mill Yashima et al (1988) and Nomura et al (1991) estimated the sizedependent rates of breakage of particles contained in ball mills using singleparticle slow compression data and experimental measurements of impact energy spectra using load sensors positioned in the shell of a lab mill, showing someA Review of Advanced Ball Mill ModellingSep 12, 2020 Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTubeball mill internal parts and lifting liner details YouTube

Ball Mills

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll If a ball mill contained only coarse particles, then 100% of the mill grinding volume and power draw would be applied to the grinding of coarse particles In reality, the mill always contains fines: these fines are present in the ball mill feed and are produced as the particles pass through the millMODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLINGInternal View Of Ball Mills bbrecycleit Internal View Of Ball Mills We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment Cement Ball Mill Grinding Internal PhotoThese commercial duty ball mills are built to withstand the rigors of everyday use The hobbyist pyro will enjoy a lifetime of service from our ultra heavy duty mills The internal shape of the barrels ensures even distribution of contents and media and guarantees great results! If you are working with a pvc pipe / homBall Mills – PyrosuppliesThe ball load should be 4058% of the total internal mill volume, and the material to be ground should fill only the voids between the balls (a maximum of twice the ball space) Viscosity, the order of filler addition, and the quantity of material should be chosen so as not to cause a viscosity increase above the specified range, since the Mill Charge an overview ScienceDirect Topics

how ball mill works internaly worldcrushers

May 14, 2013 ball mill how does ball mill works ? ball mill grinds material by pebbles and ball scats pass through the internal mill in current the wear caused by This entry was posted in Uncategorized Bookmark the permalink From a control point of view, a ball mill grinding circuit represents an and internal process variables which repr when grinding in a ball mill, the reduction in size occurs according to (PDF) Grinding in Ball Mills: Modeling and Process ControlBall Mill (Side View) magnetic separator fed through the ball mill drum, heavy duty balls inside crushing ball mill inside view invest cost hello,I would like to learn about crushing ball mill inside view invest cost crushing liming 6150 vsi crusher invest cost; crushing ball mill india make CAT Crushers Ball Mill Inside View Crusher Mills, Cone Internal Structure of the Grid Ball Mill XinHai Views (85) Ball mill is characterized by low speed, high load and strong impact, so the main shaft is usually used sliding bearing And according to the working characteristics of the mill, a lubricating system is installed in the ball millInternal Structure of the Grid Ball MillxinhaiMay 14, 2013 ball mill how does ball mill works ? ball mill grinds material by pebbles and ball scats pass through the internal mill in current the wear caused by This entry was posted in Uncategorized Bookmark the permalink how ball mill works internaly worldcrushers

Ball mill PyroData

A ball mill, a type of crusher, is a cylindrical device used to grind chemicals or mix compositions Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium, ideally non sparking milling media like lead balls An internal cascading effect reduces the material to a fine powderInternal View Of Ball Mills bbrecycleit Internal View Of Ball Mills We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment Cement Ball Mill Grinding Internal PhotoGrinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911MetallurgistAn overfilling indicator for wet overflow ball mills For a ball mill with an internal diameter smaller than 59 m, the volumebased residence time threshold is set at 2 min; and for a ball mill larger than 59 m in diameter, the threshold is set at 1 min In addition to being incorporated in ball mill models to warn of internal mechanics of ball millsThe total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or cylindrical wet ball mill machine manufacturer INUSTI cylindrical wet ball mill machine manufacturer internal cylindrical wet ball mill machine

8 Points A Ball Mill With An Internal Diameter Of

Question: 8 Points A Ball Mill With An Internal Diameter Of 1,200 Mmo Loaded With Balls Of 70 Mm Diameters, Compute For The Critical Speed In Revolution Per Minute (8Pts) 0 Latest view of Segilola Construction site Check in here frequently for construction updates Welding Installation of CIL/Leach Tanks / Received Delivery of Ball Mill, Sag Mill Other equipment February 18, 2021 February 18, 2021 Installation of Windows and Internal Notes From the Field Thor Explorations LtdThe ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill These mills are Pulverizer WikipediaMill Critical Speed Determination The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell : Mill Critical Speed DeterminationSiemens has provided about 80 SIMINE Gearless mill drives to the mining industry since 1980 In these thirtyplus years, SIMINE Gearless mill drives have accumulated a combined total of over 500 years in operation time – and this number is steadily growing even as you read this This is a benchmark we are immensely proud of Your benefitsGearless Mill Drives Beneficiation Siemens Siemens Global

Modeling and Simulation of Whole Ball Mill Grinding Plant

Jan 17, 2014 Abstract: This paper introduces the development and implementation of a ball mill grinding circuit simulator, NEUSimMill Compared to the existing simulators in this field which focus on process flowsheeting, NEUSimMill is designed to be used for the test and verification of grinding process control system including advanced control system such as integrated control