Case

of principle of iron ore processing at vale

2022-01-04T21:01:09+00:00

Dry Processing Vale

Dry Iron Ore Processing Dry processing at Vale In the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing production Today, most of our iron ore production (about 60%) is through dry processingNov 13, 2020 Brazil's Vale and China's Ningbo Zhoushan Port have signed a deal to invest around 43 billion yuan ($6506 million) in iron ore storage and processing facilities in Vale, Chinese port sign $651 million deal on iron ore RIO DE JANEIRO, Feb 5 (Reuters) Using pioneering dry iron ore processing technology, Brazilian miner Vale SA’s wholly owned New Steel plans to put its first industrial plant into operation inVale's New Steel expects first plant startup in 2022 ReutersJan 24, 2020 The principle components of iron ore are hematite and magnetite Taconite is a lowgrade iron ore Iron ore is not strong enough for construction and other purposes, so How the Iron Ore Market Works (VALE, RIO)May 15, 2019 in IRON ORE AND MANGANESE, News Vale has invested nearly R$ 66 billion * (US$ 175 billion) installing and expanding the use of dry processing, using natural moisture, in iron ore production in its operations in Brazil over the last 10 years By not using water in the process, no tailings are generated and, therefore, there is no need for damsVale to invest 11 billion reais in dry iron ore processing

Iron ore wars: the fall of Vale and the rise of Rio Tinto

May 05, 2020 Vale has finally lost its position as the world’s largest iron miner The Brazilian mining giant saw its production crater in 2019, as the tragic impacts of a collapsed tailings dam at its Brumadinho operation were felt across the iron ore sector 300 people were killed or left missing by the disaster, sparking internal investigations and external outrage as Vale’s reputation crumbledDec 02, 2020 Vale (NYSE: VALE) announced on Wednesday it expects to produce 300305 million tonnes of iron ore this year, missing a previously lowered 2020 target of at least 310 million tonnesVale reduces 2020 iron ore output forecast Jul 23, 2019 Vale sold 3655 million tonnes of iron ore products, including pellets, in 2018, easily eclipsing the 338 million tonnes sold by Rio from the PilbaraRio Tinto to take iron ore crown as Vale strugglesIron making The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention here Alternative methods known as direct reduction are used in over a score of countries, but less than 5 percent of iron is made this wayIron processing Iron making BritannicaJan 24, 2020 The principle components of iron ore are hematite and magnetite Taconite is a lowgrade iron ore Iron ore is not strong enough for construction and other purposes, so raw iron is alloyed with How the Iron Ore Market Works (VALE, RIO)

About Vale

Vale is the world's largest producer of iron ore, pellets, and nickel Our trains transport more than one million passengers on VitoriaMinas railroad and Carajás railroad every year Our global workforce comprises around 120,000 direct and thirdparty employeesVale produces the best quality iron ore in the world Business Mining; It aims to establish procedures to guide the succession process of the Chief Executive Office (“CEO”) of Vale SA (“Vale” or “Company”) to ensure the continuity of the Company's business, as well as alignment of such process with corporate governance best Policies and corporate documents ValeOn November 17, Vale inaugurated the Pico Block plant, the first pilot plant for civil construction products made from tailings from mining activities The plant set up at the Pico mine, in the city of Itabirito, Minas Gerais, is designed to foster the circular economy within local iron ore processing activitiesVale opens Pico Block plant to produce civil construction Vale has finally lost its position as the world’s largest iron miner The Brazilian mining giant saw its production crater in 2019, as the tragic impacts of a collapsed tailings dam at its Brumadinho operation were felt across the iron ore sector 300 people were killed or left missing by the disaster, sparking internal investigations and external outrage as Vale’s reputation crumbledIron ore wars: the fall of Vale and the rise of Rio TintoThe Method Vale Iron Ore Mineralogical Characterization System Analytical Methods Optical Microscopy and Digital Image AnalysisLCM evaluates the microstructure of iron ore, sinter, pellets in order to understand their characteristics and behavior in the agglomeration process, and the correlation with conventional quality parameters 44The Companhia Vale do Rio Doce PART X IRONMAKING COURSE IRON

Climate Change Vale

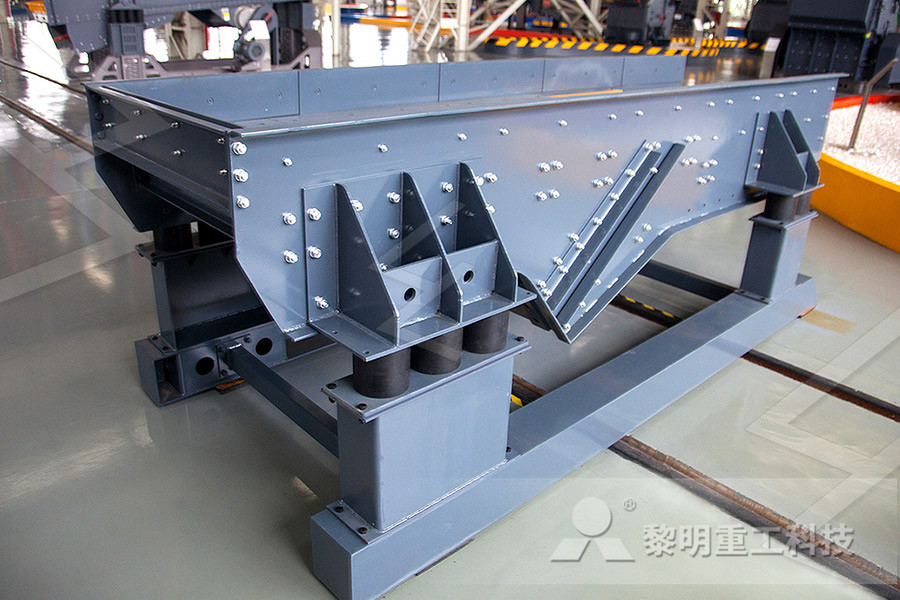

Vale’s iron ore mines located in Brazil have ores with very high iron (Fe) content and low slag content Consequently, Vale’s iron ore emits less carbon when processed in steel mills For instance, S11D Eliezer Batista Complex in Carajás produces iron ore with 667% Fe content, besides being the biggest iron ore project in the world In a corporate filing, Vale also reaffirmed its 2019 iron ore and pellets sales guidance of 307 million to 332 million tonnes, and said that sales should be around the midpoint of that target Brazil's Vale to restore full Brucutu mine output after –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore ProcessingProcessing plants such as those of Roy Hill are characterized by a high number of screening devices In fact, 16 banana screens are used in that plant alone Fig 9 shows a 40 Mta iron ore processing plant operated by Vale in the Carajas Mine The photo shows parallel linear vibrating screens for Advances in screening technology in Mineral ProcessingAug 25, 2020 The highly polluting process of making steel involves adding coking coal to iron ore to make the alloy, and is responsible for up to 9% of global greenhouse emissions ValeVale opens iron ore grinding hub in China

GEOTECHNICAL PARAMETERS OF IRON ORE TAILINGS FROM

Vale has 19 iron ore mines and 10 industrial beneficiation plants in the QF region These produce almost 200 million tons per year of iron ore, which represents approximately 70% of the total production in the region (DNPM, 2012; Vale SA, 2012) Production is forecast to increase approximately 10% between 2013 and 2017, and 50% by 2030Nov 13, 2020 Brazil's Vale and China's Ningbo Zhoushan Port have signed a deal to invest around 43 billion yuan ($6506 million) in iron ore storage and processing facilities in Vale, Chinese port sign $651 mln deal on iron ore storage Media Statement on the Iron Ore Processing (Mineralogy Pty Ltd) Agreement Act Wednesday, 19 August 2020 Last week, Parliament passed a law which challenges fundamental legal principles The law unilaterally amended a state agreement for the first time in some sixty years It exempted the State from defined liabilities, removed potential Media Statement on the Iron Ore Processing (Mineralogy Pty They are the world’s largest producers of iron ore, iron pellets, and nickel, and they are the largest producer of manganese in Brazil Despite their size and reach, Vale is committed to becoming one of the safest and most reliable mining companies in the world, always acting with due regard to the basic principle that life matters mostVale Cmmits $3 Billion to Dry Iron Ore Processing SteqTechMar 12, 2021 BRASILIA, March 12 (Reuters) Brazilian miner Vale SA said on Friday it has begun the process of increasing iron ore production at the Timbopea site, part of its Mariana complex In a securities filing, Vale said iron ore production capacity at the site should return to 12 million tons a year once the commissioning period is over, which it Brazil's Vale begins increasing iron ore output at

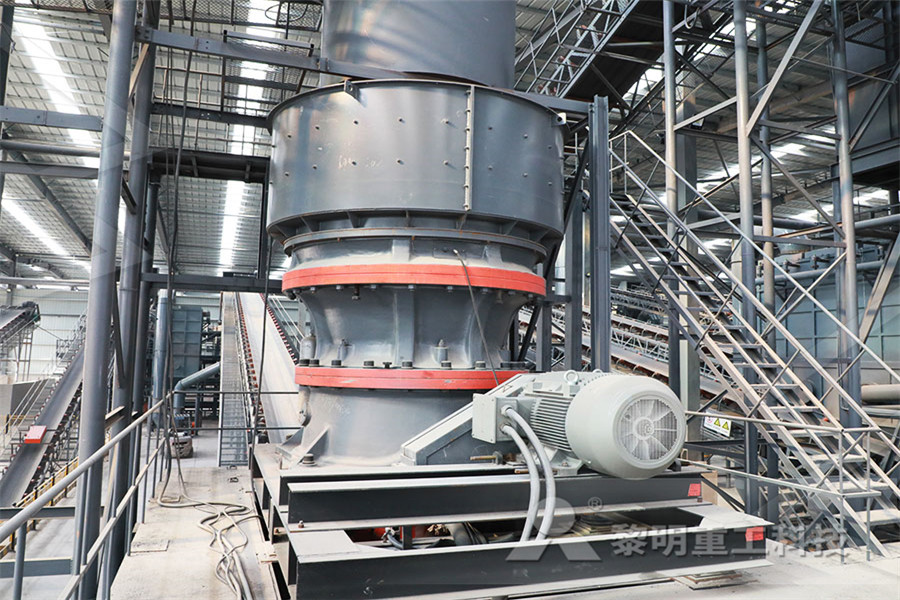

Vale starts dry iron ore concentration pilot with New

Vale has inaugurated its new dry pilot plant for processing iron ore in Minas Gerais, Brazil, as it continues to reduce its use of water in ore and waste processing The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel – a company Vale acquired in late 2018 Apr 19, 2019 Therefore, the mining of iron ore has been controlled by several large companies Iron ore is the main component of steel and accounts for 95% of the world’s metal use each year The world’s largest single iron ore producer is the Brazilian mining company called Vale, which produces more than 350 million tons of iron ore per yearHow Is The Iron Ore Mined? FTM MachineryA significant proportion of Brazil’s iron ore does not require much processing, especially in the Para state, home to Vale’s Northern System However, most of the country’s iron ore is produced in the Minas Gerais, a state dominated by a type of ore called Itabirite that has an Fe content between 30–58%Vale’s dam accident to have significant impact on the iron Vale has confirmed a Reuters news report from last week stating that it would spend an additional BRL11 billion ($25 billion) on dry iron ore processing over the next five years The company said it has invested nearly BRL66 billion installing and expanding the use of dry processing, using natural moisture, in iron ore production in its operations in Brazil over the last 10 years and it Vale exploring dry stacking/magnetic separation to The extraction of iron from its ores is quite a technical process The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high temperature in a blast furnace These materials are loaded into the blast furnace from the top while a blast of hot air is introduced into it from beneath via small pipes known as tuyeresProcesses and Procedures in the Extraction of Iron

Iron ore extraction techniques ScienceDirect

Jan 01, 2015 The seaborne iron ore trade accounted for 58% of this production China alone was importing some 65 Mt per month Over 35% of iron ore production during 2012 came from the mines of three large international producing companies, Vale, Rio Tinto, and BHP Billiton (United Nations, 2013) In national terms, at the present time, China, Australia May 15, 2020 The cast iron is usually extracted from its oxide ore (haematite) This process involves the following steps: 1) Concentration The ore is crushed in jaw crushers and is broken to small pieces of about 1 inch in size The crushed ore is concentrated by gravity separation process in which it is washed with water to remove clay, sand, etc 2 Extraction of Iron Class 12, General Principles and Carajás Mine, the world’s largest iron ore mine, is located in the state of Para in northern BrazilFully owned by Brazilian miner Vale (CVRD), it holds 72 billion metric tonnes of iron ore in proven and probable reserves The Carajas region boasts the richest reserves and concentrations of iron ore anywhere in the world and was discovered entirely by accident in the late1960s when a US Carajas Iron Ore Mine, Para, Brazil Mining TechnologyJul 25, 2019 Interruptions to Vale’s Brazilian operations earlier this year, after the collapse of a tailings dam caused the death of more than 200 people and took more than 30m tonnes of annual iron ore production out of the market, are partly to blame for iron ore price increases Vale subsequently received authorisation to restart its Brucutu mine, but Iron ore: Confounding the expectations of experts Edisonthe steelmaking process Iron production is a long process that involves knowledge of the ore throughout its life cycle, from the production of pig iron to the final product, steel To date, great efforts have been focused on improving knowledge of iron ore reserves and iron Impact of quality of iron ore lumps on sustainability of

Vale Approves $15B Serra Sul Iron Ore Project; RBC Bullish

With iron ore markets tight and margins at astronomical levels, Vale SA (VALE) has announced that its board of directors have approved the implementation of the Serra Sul 120 Project, in Canaã The country’s iron ore production came in at 930 million metric tons (MT) of usable iron ore in 2019, or 580 million MT of iron content, according to the US Geological SurveyWays to Invest in Iron Ore Supply, Demand, Stocks INN